Fasteners and Machining: Secret to Effective and Trustworthy Manufacturing

Fasteners and Machining: Secret to Effective and Trustworthy Manufacturing

Blog Article

Navigating the World of Fasteners and Machining: Methods for Precision and Rate

In the detailed world of bolts and machining, the pursuit for precision and speed is a continuous difficulty that requires thorough interest to information and strategic planning. From comprehending the diverse array of fastener kinds to choosing ideal products that can withstand extensive needs, each action in the process plays a crucial function in attaining the preferred end result.

Understanding Bolt Kind

When picking fasteners for a project, recognizing the numerous types readily available is crucial for making certain optimal efficiency and reliability. Bolts are made use of with nuts to hold materials with each other, while screws are functional fasteners that can be made use of with or without a nut, depending on the application. Washing machines are essential for dispersing the lots of the bolt and preventing damage to the material being fastened.

Choosing the Right Materials

Understanding the value of choosing the best products is vital in guaranteeing the ideal efficiency and reliability of the chosen fastener types reviewed formerly. When it comes to fasteners and machining applications, the material choice plays an essential function in figuring out the general toughness, durability, corrosion resistance, and compatibility with the intended environment. Different materials provide varying properties that can considerably affect the performance of the fasteners.

Common materials utilized for fasteners include steel, stainless steel, titanium, aluminum, and brass, each having its special staminas and weaknesses. Steel is renowned for its high strength and resilience, making it suitable for a wide range of applications. Stainless-steel uses superb deterioration resistance, suitable for atmospheres prone to moisture and chemicals. Light weight aluminum is light-weight and corrosion-resistant, making it suitable for applications where weight decrease is essential. Brass is often selected for its visual allure and excellent conductivity. Titanium is known for its phenomenal strength-to-weight ratio, making it optimal for high-performance applications. Selecting the best material involves taking into consideration variables such as stamina needs, ecological conditions, and budget restrictions to guarantee the desired performance and longevity of the bolts.

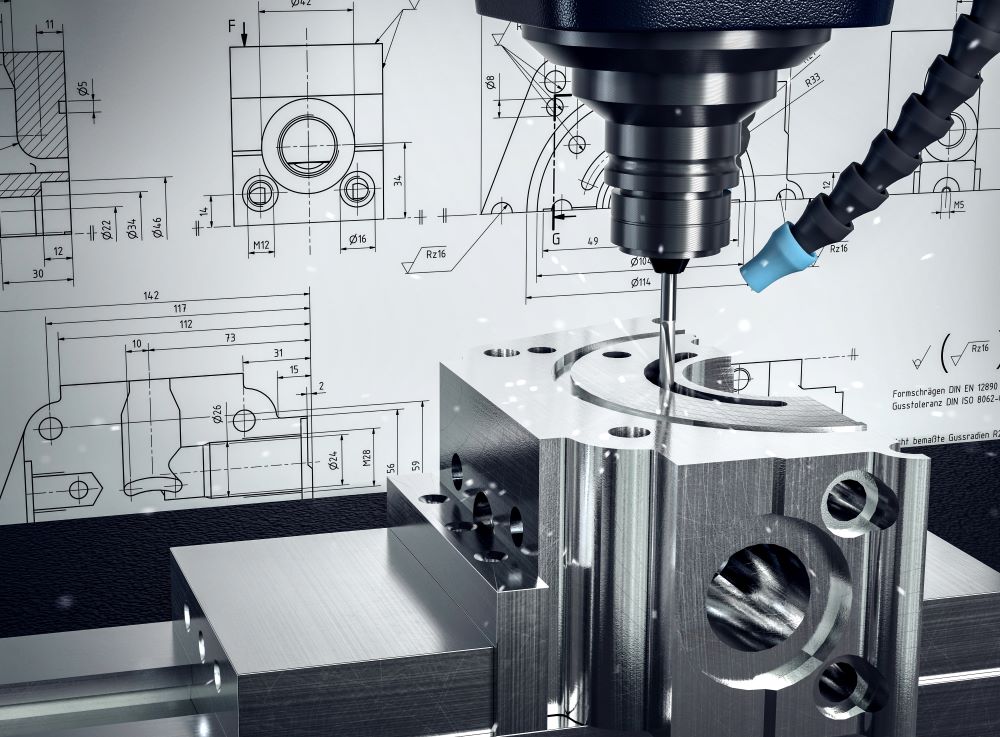

Accuracy Machining Techniques

In addition to CNC machining, various other precision methods like grinding, transforming, milling, and drilling play crucial roles in fastener manufacturing. Grinding helps accomplish great surface coatings and limited dimensional tolerances, while turning is frequently made use of to develop cylindrical elements with precise diameters. Milling and boring procedures are vital for forming and producing openings in bolts, ensuring they satisfy specific requirements and feature correctly.

Enhancing Rate and Effectiveness

To optimize bolt production procedures, it is necessary to improve procedures and implement effective approaches that complement precision machining techniques. One essential approach for improving rate and performance is the application of lean production principles. By minimizing waste and focusing on constant renovation, lean practices assist get rid of traffic jams and maximize workflow. In addition, buying automation modern technologies can significantly improve manufacturing rate. Automated systems can deal with repetitive tasks with accuracy and rate, allowing employees to concentrate on more complex and value-added tasks. Taking On Just-In-Time (JIT) supply monitoring can likewise enhance efficiency by making sure that the right materials are available at the correct time, minimizing excess supply and lowering preparations. In addition, promoting a culture of collaboration and interaction amongst team participants can boost general efficiency by advertising openness, analytical, and development. By incorporating these strategies, manufacturers can accomplish a balance in between speed and accuracy, eventually improving their one-upmanship in the fastener market.

Quality Assurance Steps

Applying extensive quality control measures is essential in making sure the dependability and consistency of bolt products in the manufacturing process. Fasteners and Machining. Quality control steps encompass numerous stages, starting from the choice of raw materials to the last evaluation of the finished bolts. This involves assessing variables such as material toughness, strength, and make-up to guarantee that the bolts meet market standards.

Normal calibration of devices and equipment is necessary to maintain uniformity in production and make sure that fasteners satisfy the needed go tolerances. Executing rigorous protocols for recognizing and dealing with non-conformities or flaws is important in stopping substandard items from entering the marketplace. By establishing a detailed quality assurance structure, producers can maintain the credibility of their brand name and supply fasteners that satisfy the greatest criteria index of performance and resilience.

Verdict

In the elaborate world of bolts and machining, the quest for precision and rate is a continuous obstacle that requires thorough focus to information and critical preparation. When it comes to fasteners and machining applications, the material option plays a crucial role in identifying the overall stamina, longevity, corrosion resistance, and compatibility with the intended setting. Precision machining her latest blog involves various advanced approaches that guarantee the tight tolerances and requirements needed for fasteners.In addition to CNC machining, various other accuracy methods like grinding, turning, milling, and exploration play essential functions in fastener production.To maximize bolt production procedures, it is important to streamline procedures and carry out effective strategies that complement accuracy machining methods.

Report this page